Taisun observes market demands and actively develops products that are both healthy and nutritious while satisfying different consumer groups. Adhering to the goals of safety, health, and taste, Taisun continues to move towards less sugar and fewer additives, meeting consumer needs with safe and simple ingredients.

Over the years, Taisun has launched many products that align with health concepts, such as the “Zhengu Yi Series” with Clean Label certification and AA additive-free certification, “Taisun Plant Sterol Sunflower Oil” which obtained health food certification, and the “Cha Chi Chu” series which uses simple ingredients without flavoring or tea powder. The annual revenue from these products is about 948 million TWD. In 2023, Taisun launched several products combining health and taste, such as “Nut Work” Oat Walnut Nut Milk, Premium Soybean Walnut Nut Milk, and “High Cereal Extract Rice Bran Oil”.

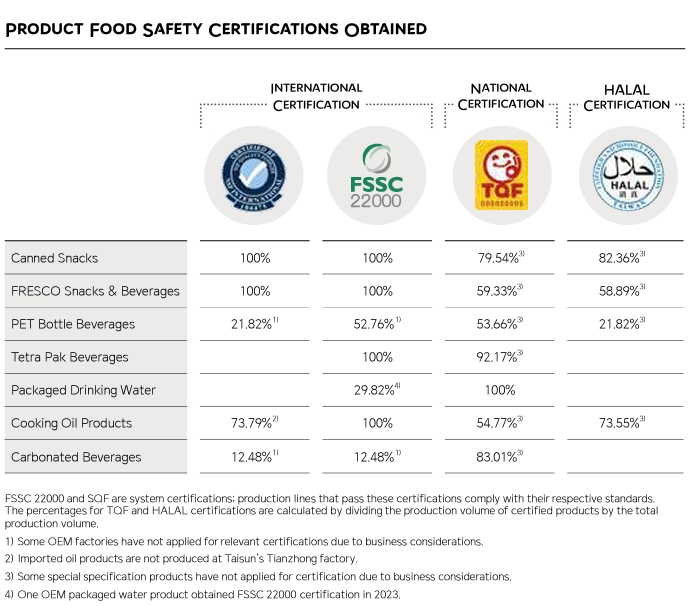

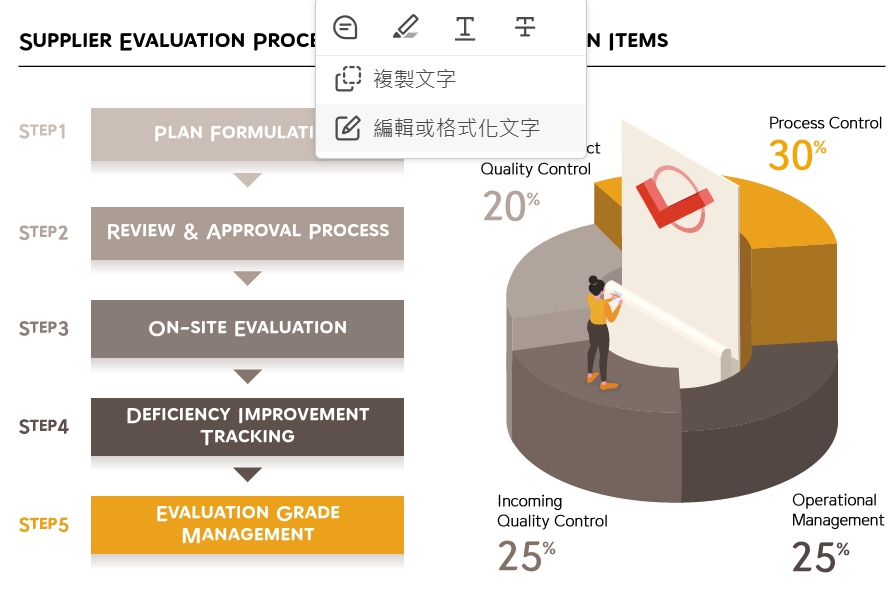

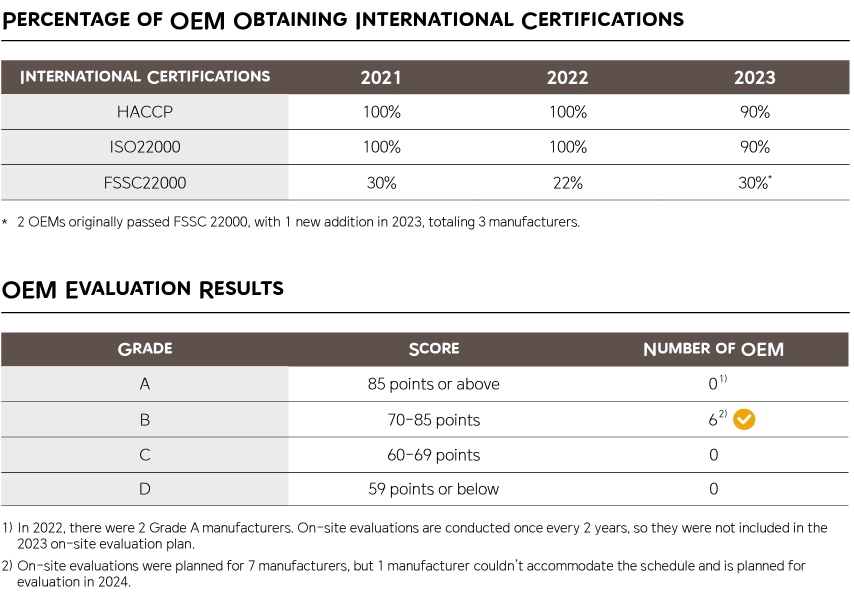

The basics of customer safety and health lie in the manufacturing process, from R&D, raw material and OEM management to process management and laboratory control, and third-party quality testing. Taisun is committed to ensuring product safety, confirming health and nutritional value, creating public trust, and minimizing risk damage from strict incoming quality assurance to post-production, striving to maintain consumer trust and company reputation.

_0-768x768-1-300x300.jpg) |

High Cereal Extract Rice Bran Oil

Bringing Health into Every Family

|

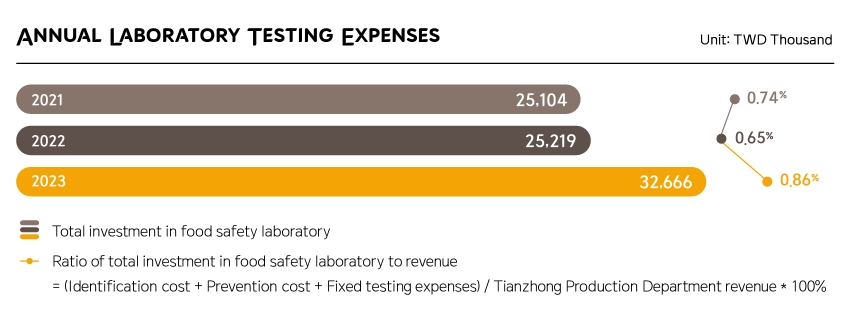

Taisun has 3 laboratories: a food laboratory, a microbiology laboratory, and a cooking oil products laboratory. The current laboratory equipment configuration complies with the “Food Factory Building and Equipment Factory Standards” announced by the Ministry of Health and Welfare. Equipment is sent to impartial units for annual calibration. Laboratories have significant influence in R&D and quality assurance stages. To enhance product quality control capabilities, Taisun improves equipment, talent, and experimental expertise. The laboratories are established based on ISO/IEC 17025, building a certified laboratory quality management system to serve as professional food and oil product testing laboratories, safeguarding food hygiene and safety quality.

1. Equipment Management

In 2023, 104 external calibrations were commissioned. Some equipment was internally calibrated by qualified trained personnel, with 222 internal calibrations in 2023.

2. Laboratory Testing Capability Compliance

| Food and Microbiology Laboratory Snacks, Beverages, Packaged Water |

Cooking Oil Products Laboratory | |

| Physical Tests | PET bottle pressure resistance leak test, high sugar content detection, carbonated drink CO2 volume measurement, can seam test, can vacuum leak test, can vacuum measurement, paper box sealing leak test, cardboard bursting strength, cap torque, microscopic projection (max 200x magnification), fresh rice analysis, color Lab value, moisture content (oven method, infrared method), T% (transmittance), HOBO temperature monitoring, specific gravity, sugar content, viscosity, weight, environmental monitoring (including HOBO temperature and humidity monitoring), canned food heat preservation test, reliability test, water quality test (including effective residual chlorine, turbidity, conductivity, hardness, salinity), sensory evaluation | Moisture, color, smoke point, absorbance, container leak test, reliability test, cardboard bursting strength, viscosity weight, bottle cap leak test, sensory evaluation, lowtemperature property test, frying test, cooking test, rising melting point, deterioration test, UV spectrophotometry for olive oil grade identification |

| Chemical Tests | pH value, total acidity titration, formaldehyde nitrogen, tea polyphenol test, allergen test, pesticide residue (organophosphorus and carbamate series pesticides) | Acid value, peroxide value, GC detection of fatty acid composition (trans fat, saturated fatty acids, unsaturated fatty acids), total polar compounds, erucic acid, iodine value |

| Microbiological Tests | Microbiological tests (including total bacterial count, E. coli, coliform, Pseudomonas aeruginosa, fecal streptococci, Salmonella, mold/yeast, spore-forming bacteria, Enterobacteriaceae), ATP fluorescence rapid microbial detection, environmental monitoring (RCS air collection test) |

3. Talent Training

| External Training Courses Related to Product Assurance | Number of Participants | Hours |

| Complete Management of Hermetic Sealing | 1 | 6 |

| Training for Crimping Hermetic Seals | 2 | 38 |

| International Seminar on Food Safety Risk Factors and Mitigation Strategies | 3 | 15 |

| Internal Auditing and Verification for Food Safety Management Systems | 1 | 6 |

| HACCP Continuous Education | 4 | 28 |

| SPC Statistical Process Control Training | 2 | 12 |

| FSSC/ISO 22000 Internal Auditor Training for Food Safety Management Systems | 2 | 12 |

| Advanced Microbiology Testing Course (Pathogen Testing) | 1 | 17 |

| External Training for the Latest Requirements of FSSC 22000 (Version 6) | 3 | 18 |

| Laboratory Certification Training for ISO/IEC 17025 | 3 | 54 |

| Seminar on Measurement Uncertainty | 1 | 12 |

| Seminar on Corrective Action Implementation | 2 | 12 |

| Internal Review Seminar for the Laboratory Department | 1 | 12 |

4. Laboratory Testing Related Expenses

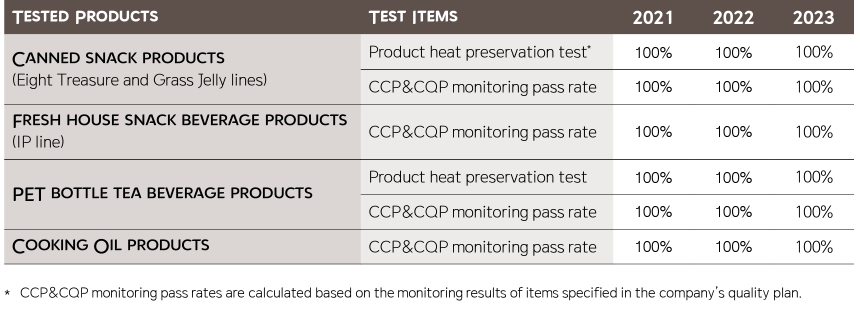

5. Self-Inspection Pass Rate

All of Taisun’s product labels are collected from relevant information from various departments by the responsible unit, then sent to design for product packaging file design and layout. After the product packaging layout is completed, it is confirmed at least twice through email and online electronic forms with the marketing, legal, R&D, quality assurance, production, and accounting departments to ensure that the packaging labels comply with regulations.

In 2023, there were 310 product packaging label reviews, including 14 for canned snack products, 143 for beverage products (including 58 room temperature beverages, 65 refrigerated beverages including PE and refrigerated snacks, 20 carbonated beverages), 38 for oil products, 103 for water series products, 6 for commercial room temperature products, and 6 for others (concentrated liquid).

To ensure the safety and quality of every can of product in consumers’ hands, Taisun samples products and raw materials annually and sends them to third-party certification units for inspection, such as local health bureaus, the Food Industry Research and Development Institute, and third-party certification units (like SGS, Intertek). In 2023, a total of 1,155 samples were sent for inspection. For source management, water source quality was inspected 18 times, raw material food safety and hygiene items were inspected 365 times, and packaging materials were inspected 71 times, all passing the inspections. Furthermore, to control product risks, Taisun strictly monitors oil product safety, with a total of 283 oil products sent for inspection, achieving a 100% pass rate. Other product categories such as refrigerated beverages (56 inspections), room temperature beverages (31 inspections), canned foods (281 inspections), packaged drinking water (19 inspections), and snacks (31 inspections) all achieved a 100% pass rate.

In addition to self-initiated external product inspections, in terms of food safety work management, Taisun’s food factory and oil factory underwent 4 mandatory audits by local government and governmentcommissioned units in 2023, all meeting requirements. To continuously improve and maintain food safety quality certifications, Taisun underwent 8 food safety quality audits by third-party certification units in 2023. When deficiencies were found during audits, Taisun actively made improvements and passed all audits.