- Created healthy and low-sugar products with few additives:

|

Taisun’s Peanut Soup category comprises two varieties: the traditional Peanut Nut Soup and the Taiwan Peanut Soup, crafted using locally sourced ingredients. In 2022, Taisun, a snack expert, introduced a new product called Peanuts with Oat Milk.

This peanut soup is made with high-quality oat milk as the base, combined with large and plump peanuts and oats. It is completely free of additives, milk, and creamer, making it suitable for vegetarians and those with dairy sensitivities. Additionally, it is 100% lactose-free. Peanuts with Oat Milk is a healthy option for replenishing cereal nutrients and can be enjoyed as a breakfast, snack, or midnight snack. The sugar content per 100g is 3.5g lower than that of Peanut Nut Soup.

Additionally, it offers a refreshing taste, without being overly sweet or greasy. This makes it a healthy and delicious option. |

|

To meet consumer demand for additive-free products, Taisun introduced the Taisun Japanese Unsweetened Green Tea in 2022. This new product is made from carefully selected premium tea leaves and brewed with 100% real tea leaves. It does not contain tea extract or tea powder, and is both sugar-free and additive-free.

This offers a fresh choice for consumers who prefer unsweetened tea. The product is packaged in aluminum cans, promoting recycling and aligning with the principles of environmental protection. |

Customer safety and health are essential aspects that rely on the entire manufacturing process. This process encompasses research and development, management of raw materials and foundry, process management, laboratory control, and even third-party quality testing. Taisun recognizes the significance of product safety, values health and nutrition, and strives to establish public trust. To achieve these goals, Taisun has implemented rigorous quality control measures at the factory and endeavors to minimize risks and damages once the products have left the premises.

2. External Assurance

To guarantee the safety and quality of each can in the possession of consumers, we annually submit our sampled products and raw materials for inspection to reputable third-party entities. These include the local health bureau, the Food Industry Research and Development Institute, and certified notary units such as SGS and Intertek.

In 2022, a total of 637 product samples were sent for inspection. In terms of source management, the water quality of our water sources has been tested 21 times, and all test results have been satisfactory. In order to mitigate product risks, Taisun maintains strict control over the safety of its oil products and tea leaves.

A total of 179 oil products have undergone inspection, while the tea leaves have been inspected 96 times, all achieving a 100% pass rate. Other types of products are also subject to inspection. Beverages were inspected 25 times, PET beverage products were submitted 86 times, canned food was submitted 57 times, packaged drinking water was submitted 17 times, and snacks were submitted 32 times. All of these products achieved a 100% pass rate.

In 2022, the Taisun food plant and oil plant underwent two mandatory audits conducted by the government and government-appointed entities for food safety management. These audits included product sampling for testing.

We are pleased to report that we successfully passed all of these audits. In order to maintain continuous progress and uphold our food safety quality certification, Taisun successfully underwent a total of 11 food safety quality audits conducted by third-party impartial entities in 2022. Taisun promptly addresses any identified defects and consistently achieves a passing grade in all audits.

Taisun Products That Obtained Food Safety Certification in 2022

Note: 1. The OEM has not yet applied for the relevant certification due to business considerations.

Note: 2. Imported oil products are not produced in Taisun Tianzhong Plant.

Note: 3. For business considerations, certification has not been sought for special specification products.

Note: 4. The percentage of TQF and halal certified products is determined by dividing the volume of certified products by the total production volume. FSSC22000 and SQF are certification systems, and the production lines that have obtained these certifications comply with their respective regulations.

3. Confirm the use experience and ensure product quality and safety through the toll-free hotline management mechanism:

The toll-free hotline customer service personnel received a total of 368 customer complaints regarding product conditions. These complaints included 107 cases related to factors unrelated to production and 261 cases involving the investigation of anomalies. All of these cases were addressed appropriately, with a focus on improving our response to such issues.

Raw materials are the foundation of food safety. By meticulously choosing our suppliers, we can guarantee consistent quality, minimize risks and threats to food safety, and safeguard our reputation and sustainable growth.

Taisun conducts regular supplier audits to assess their performance and ensure high-quality raw materials. This includes retaining reliable suppliers and eliminating those that do not meet our standards. Additionally, we closely monitor the pass rate of raw materials entering the factory.

Procurement Management

- Supplier Management Strategies

To mitigate the potential for cost increases or disruptions in supply, we engage with a variety of suppliers for our procurement needs. By establishing enduring partnerships with suppliers who offer competitive pricing, we ensure stability in both price and quality, while minimizing the risk associated with managing the supply of raw materials. In addition to nurturing our existing relationships with reliable suppliers, we actively seek out new suppliers who can meet our requirements.

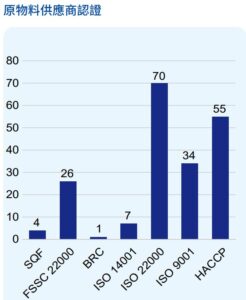

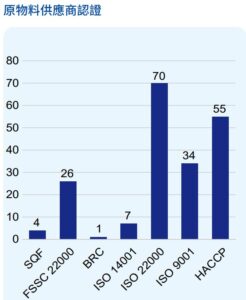

The selection of raw material suppliers undergoes rigorous evaluation. Our suppliers must comply with legal regulations, and their products or services should align with our production needs, offering competitive prices and a strong level of cooperation. Our R&D and quality assurance units have thoroughly reviewed and verified the entire raw material procurement process. To enhance our quality management standards, we prioritize suppliers who possess Food-grade-related certifications.

Suppliers are required to sign a Integrity and Sustainable Management Commitment. This commitment encompasses business integrity, labor rights, environmental protection, consumer protection, and respect for the intellectual property rights of third parties. Its purpose is to encourage suppliers to prioritize corporate social responsibility. The signing rate for the Integrity and Sustainable Development Commitment surpassed 89.82% among suppliers with transaction amounts of NT$100,000 or more in 2022.

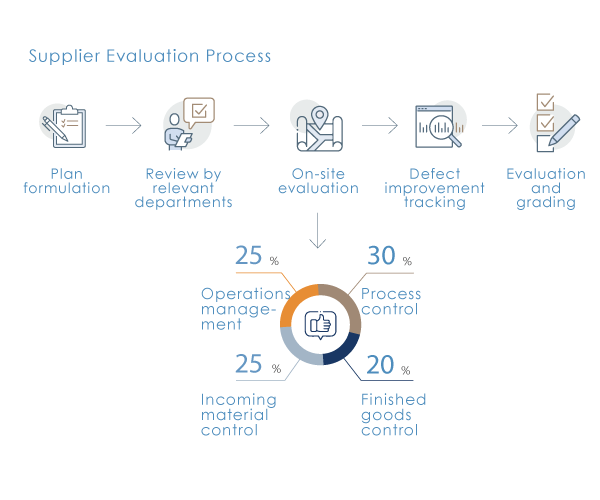

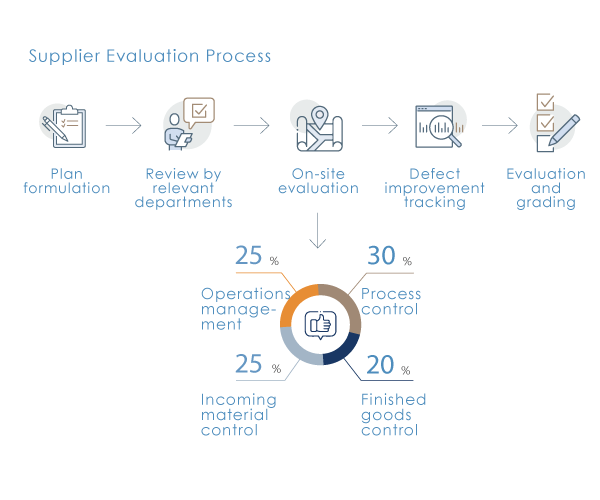

2. Supplier evaluations

Every year, we convene a team of relevant personnel to assess our suppliers. This process involves creating a supplier evaluation plan and conducting

evaluations either in writing or on-site, in accordance with the plan. We expect our suppliers to propose improvement measures or plans to address any defects

and ensure the quality of deliveries.

The evaluation results serve as a basis for future collaboration. In 2022, our evaluation was centered on social issues and environmental protection. The aim was to encourage suppliers to prioritize their social responsibility

and adhere to ethical, legal, and environmental standards. Our goal is to foster sustainable partnerships with suppliers through a practical management

approach.

3. Inspection of Raw Materials

The quality assurance personnel inspect incoming raw materials in accordance with the specifications. If the materials fail to meet the acceptance criteria, the supplier will be notified and the materials will be returned.

Accepted raw materials undergo further screening during production to ensure quality control.

Raw Material Suppliers’ Certifications

4. Evaluation Results

Due to the pandemic in 2022, on-site evaluation was not feasible. Instead, evaluations were carried out through written or online means. A total of 58 suppliers, representing 31.02% of the raw materials suppliers engaged in procurement activities in 2022, were assessed.

| Level |

Score |

Management method |

2022 evaluation results |

| A |

90-100 |

Prioritized for inquiry and purchase |

11 |

| B |

80-89 |

Price inquiry, and purchase |

39 |

| C |

70-79 |

Encouraged to improve quality management standards |

8 |

| D |

60-69 |

Reduce purchases and provide guidance about quality if needed |

0 |

| E |

<60 |

Eliminated |

0 |

5. Raw Material Evaluation Status

| |

Agricultural

products |

Carton |

Packaging

containers |

Juice

concentrate |

Oils |

Others |

Average |

Pass rate

of incoming

materials |

99.2% |

99.6% |

99.4% |

100% |

100% |

99.8% |

99.5% |

| Pass rate of materials used |

98.3% |

99.9% |

99.9% |

100% |

100% |

99.8% |

99.8% |

OEM Management

Taisun carefully chooses outstanding OEMs in accordance with the Operational Standards for the Evaluation and Guidance of Outsourced OEMs. Taisun engages with appropriate OEMs based on product characteristics. OEMs must meet specific criteria before being considered as candidates. These criteria include HACCP certification, a valid factory registration certificate, and a business registration certificate. For beverage products, a water rights certificate is required. Additionally, OEMs should have no record of violations. Taisun encourages original equipment manufacturers (OEMs) to enhance their factory management practices in order to comply with international standards and ensure that the quality of their products meets regulatory requirements.

Taisun is obligated to visit all OEMs participating in the co-production program in order to evaluate the operational conditions, perform quality testing, and validate the products. The items to be verified are as follows:

inspection of sampled products from each batch, daily production audit (graded management), GMP audit (graded management), quality meeting communication and review (graded management), and annual evaluation (graded management). Arrange for quality assurance personnel to visit the OEMs periodically to monitor the quality. In addition to the OEMs’ inspections, samples of the products are taken and sent back to Taisun for inspection. This is done to ensure that the products meet our requirements and to prevent any defective products from entering the market, which could negatively impact the Company’s reputation.

Every year, Taisun develops an evaluation plan and conducts on-site inspections at the OEMs. These evaluations assess the organization and personnel, plant facilities and factory environment, machinery and equipment, hygiene management, process management, and quality management. The results of these evaluations serve as the foundation for future cooperation and graded management.

In 2022, nine OEMs signed OEM contracts. Due to product adjustments made by Taisun, the total number of OEMs decreased by one compared to 2021. It is worth noting that all OEMs have successfully obtained 100% of the necessary food safety certificates. We are actively promoting our OEMs to acquire food safety and quality certification. The current status of the nine OEMs that have successfully obtained international certification is as follows:

Percentage of International

Certifications |

HACCP |

ISO22000 |

FSSC22000 |

| 2020 |

100% |

100% |

27% |

| 2021 |

100% |

100% |

30% |

| 2022 |

100% |

100% |

22% |

In 2022, a total of seven original equipment manufacturers (OEMs) successfully completed on-site audits, representing 78% of all OEMs. Among them, five OEMs were assessed at the B level, while two OEMs attained the A level.

| Level |

Score |

2022 |

| A |

85 points(inclusive) or higher |

2 |

| B |

70 points(inclusive)-85 points |

5 |

| C |

60 points(inclusive)-69 points |

0 |

| D |

59 points (inclusive) or lower |

0 |

1. To ensure compliance with food safety and health regulations and standards

In 2022, there were no reports, violations, fines, recalls, or product delisting in connection with the Act Governing Food Safety and Sanitation, the Standards for Specification, Scope, Application, and Limitation of Food Additives, Methods of Test for Food Microorganisms, Product Liability Insurance for the Food Industry, the Regulations on Good Hygiene Practice for Food (GHP), the Sanitation Standard for Food Utensils, Containers, and Packages, the Standards for Pesticide Residue Limits in Foods, the Sanitation Standard for Contaminants and Toxins in Food, and the Sanitation Standard for Microorganisms in Foods, among other laws and regulations on food safety and manufacturing.

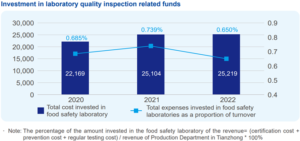

2. Laboratory Management

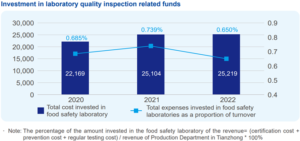

Taisun operates three laboratories: the Food Laboratory, Microbiology Laboratory, and Oil Laboratory. These laboratories are equipped with instruments and equipment that meet the Ministry of Health and Welfare’s Establishment Standards of Construction and Equipment of a Food Factory. Additionally, all instruments and equipment undergo annual calibration and approval by an impartial institution. The laboratory plays a crucial role in research and development as well as quality assurance. To strengthen our ability to control product quality and enhance our equipment, talent, and experimental capabilities, Taisun has established a certified laboratory quality management system in accordance with ISO/IEC 17025. This system serves as a professional testing laboratory for food and oil products, ensuring the quality and safety of food hygiene.

1. Track and Trace

To minimize potential losses in the event of a major product abnormality, Taisun promptly traces the supplier of food materials associated with any problematic product. Additionally, the Company swiftly traces the flow of products from the problematic food materials. By efficiently identifying and removing defective products, Taisun aims to safeguard consumer health and minimize any potential damage to the company. When a defective product is promptly recovered, it is immediately traced back to its root cause in order to prevent any future abnormalities. Taisun has successfully implemented a tracking system in compliance with the Identification and Traceability Management Procedures. As a result, Taisun is now able to promptly identify and address any abnormal flow direction within a 24-hour timeframe. Additionally, Taisun has efficiently established a recovery and shelving network.

In 2022, we conducted a total of 20 simulated recycling tests to cover all product types, including OEM products. These tests achieved a 100% recycling rate, ensuring that the production history of the products can be tracked and traced.

To ensure the tracking and tracing of product flow and the identification of raw material sources, the government mandates that oil and fat manufacturers, tea beverage manufacturers, and soybean, oil, and tea importers upload every batch of their products onto the tracking e-platform. We have complied 100% with this requirement by uploading a total of 280 batches from the manufacturing industry and 40 items from the importing industry onto the Food and Drug Administration’s Tracebook system in 2022.(https://ftracebook.fda.gov.tw/)

2. Confirm the use experience and ensure product quality and safety through the toll-free hotline management mechanism:

The toll-free hotline customer service personnel received a total of 368 customer complaints regarding product conditions. These complaints included 107 cases related to factors unrelated to production and 261 cases involving the investigation of anomalies. All of these cases were addressed appropriately, with a focus on improving our response to such issues.

- Taisun Facebook (Can communicate via private messaging):https://www.facebook.com/TaisunFB

- Customer and consumer service hotline:0800-079-080

- Company mailbox:taisun1@taisun.com.tw